The lifeblood of Tom Joyce’s work is iron, from the molecular to the colossal. Iron, by mass, is the most common element on Earth, and it plays a role in the cosmos, our blood, industry, weaponry, perhaps even our memory. Joyce is quick to point out the material’s associative dexterity, whether historical, political, biological, environmental. His extensive and diverse work, not only in sculpture but in photography, printmaking, and new media, points to his ongoing exploration of the possibilities—technical and metaphoric—that can be wrought from this medium.

The artist has been working with iron since his early teenage years, and having arguably mastered the technologies of traditional blacksmithing, his more recent work is engaged in quickly evolving technologies such as laser scanning and sand-cast 3-D printing. As his methods have evolved from the hand-forged tool to large scale manufacturing facilities and new media, the exhibition Everything at Hand (July 28–December 31, 2017) on view at Santa Fe’s Center for Contemporary Arts is part retrospective, part revolution. Joyce’s work is moving in new, alternating directions, but always with a compass needle fixed on investigating the implications and metaphors that permeate this fundamental element. Iron is riddled throughout our world and our bodies, often invisible; Joyce’s work pulls these relationships—formal, structural, conceptual—into view.

Tom Joyce: I’ve spent forty-five years in studios, Brussels, here, and in El Rito, where I first started forging, and all the tools that you see here are familiar friends. Most of them I made; they were designed for very specific projects. Because the nature of the work has changed so much, I’ve been investigating what it means to have this history tied to a place, not only with objects and tools, but also steeped in the processes I use. Right now, we’re going through the studio and pulling out all the tools that have specific names and purposes and scanning them. We’re making 3-D scans and then making 3-D prints of the tools in a translucent material to create an installation of all these familiar friends, but as ghosts. It’s about loss, due to technological innovation, that a lot of artists are working with. Manufacturing is working with the nature of these hand skills that have taken decades of practice to develop, and are also on the wane. There’s something that’s moving away at the same time as all of this wonderful, new, delightful information is coming forward.

Lauren Tresp: Would you say that these are basically obsolete tools?

Inside the narrow world of hand forging, they’re actually indispensable. But, inside my world, I’m not using them like I once did. The feeling I have when I walk in the studio these days is as if I’m a child again, putting my head between my legs and looking at the ceiling as if it’s the world upside down. And that’s what I want to try to convey in the show at CCA. We’re going to take a twenty-by-thirty-foot section of the studio, the hot working part of the shop, and turn it upside down, hang it from a solid armature, and suspend it upside down in the space, like stalactites. There’s a machine like this that isn’t being used right at the moment, so we’re going to take that, turn it upside down. It’s about eight thousand pounds. I’m hoping that there’ll be a double emphasis on unfamiliar forms, shapes, and tools to many of the visitors, but, at the same time, there will be something creepy and wondrous about walking into this environment that has this potential, yet is poised out of reach.

LT: I imagine that it will look somewhat futuristic, despite these being somewhat archaic.

This machine is coming up on a hundred years old; it was built in 1928. The two installations look at the tools and equipment that were once important in my work, but reframed now that I’m transitioning to a different kind of historical reference. The tools that I draw upon are still at the core and the heart of everything that I do. I like working with iron, even though at this point I also work with other materials, and I have for quite a long time. Like the newspaper sculptures that are hanging at the other end of the studio: those are twenty-three years old. I was working with books and newspaper and all kinds of print media that I felt were on the edge of this fragile state of existence. I was looking at storage systems, whether in our mind, in a book, in a CD-ROM; all of that information is held in a fragile state, and in our memory more so than any other. Fire takes a book away in an instant. Our memories fade.

I’ve learned over the years that the nano-particles of iron in our blood have everything to do with our ability to remember. UCLA just built a new center for the study of iron in our bodies, and they’re looking at how it relates to Alzheimer’s and recovery from stroke. Muscle memory is all tied to these very minute percentages of iron coursing through our bloodstream. When I think about iron, I think about it in macro/micro scales. Iron at the center of the earth keeps us in orbit around the sun, but on this micro scale it has everything to do with the ability to move through a creative space as an artist, doing our work, holding it in our minds at the same time as we’re trying to work diligently and facilely with tools.

When I think about iron, I think about it in macro/micro scales. Iron at the center of the earth keeps us in orbit around the sun, but on this micro scale it has everything to do with the ability to move through a creative space as an artist, doing our work, holding it in our minds at the same time as we’re trying to work diligently and facilely with tools.

LT: Was moving to this digital project an epiphany for you, or was it a smooth transition?

In 2013, I was doing a Kohler residency [John Michael Kohler Arts Center, Kohler, WI]. I wanted to make a casting of one of my molds turned inside out and mirrored. It was a form more complex than I was capable of producing a pattern for. I started looking into doing CT scans at a local Sheboygan hospital to render a mold. When I went to the hospital, they said, “No worries. Just bring whatever you want. We’ll run it through the CT scanner, in between humans.” I would go in between their normal operating hours, and they allowed me to do this. Those files were sent off to a place called ExOne that does 3-D printing: resin-bonded sand molds. Two weeks later I had these incredibly complicated molds delivered to me at the factory that, without that technology, I wouldn’t have been able to realize.

The engineers at Kohler had not yet encountered the resin-bonded sand 3-D printed technology. So I called several of the engineers to see the molds as soon as they arrived, and I watched the blood drain from their faces as they realized that what they were seeing was going to revolutionize their own industry over the next few years. It signaled job losses by supplanting pattern-making hand skills with robotics and 3-D printing technology. These have arrived in American factories in ways that were unprecedented even five, six years ago.

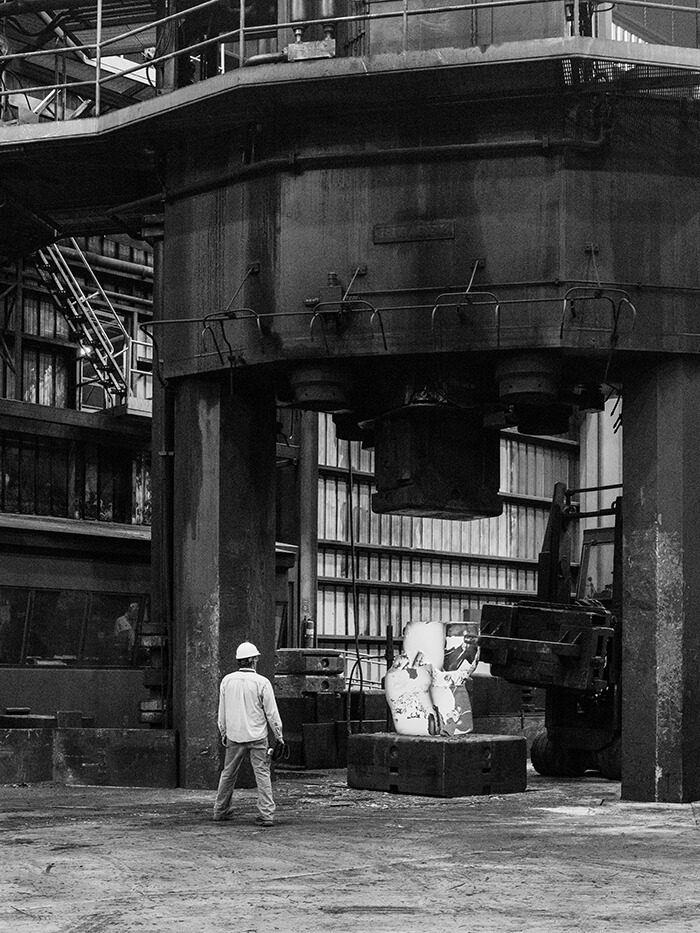

When you think about the stability of the industrial complex that gives us the goods and services that we take for granted, it’s a big deal what these kinds of technologies introduce. So I wanted to feel that, both on a relatively small scale inside my environment, and to apply that to the world that I’m now much more familiar with, working inside industry, like in the factory where I do my larger-scale forgings. The company is performing state-of-the-art forging in a 128-year-old business, and they continually adopt the latest technologies so that they’re always in step with what’s possible globally. They realize how important it is to be on that cutting edge of innovation. And to have the privilege of going to this place and feeling my finger on the pulse of what happens economically, or politically, or environmentally, which is a direct result of the kinds of commissions that find their way into this factory, it gives me more of an overarching view of what’s happening out in the world.

to have the privilege of going to this place and feeling my finger on the pulse of what happens economically, or politically, or environmentally, which is a direct result of the kinds of commissions that find their way into this factory, it gives me more of an overarching view of what’s happening out in the world.

I also used the hospital CT scans to take this hammer and make a 3-D model of it, then make a cluster of those that have stainless rods that pass through the eyes. They bypass one another in such a rigid configuration that they create an impenetrable thicket made up of twenty-three nuclei. Outside at CCA, we’re going to install this constellation of twenty-three elements. It ends up being about fifteen thousand pounds of stainless and cast iron that have this interdependent relationship to one another. If you take any of those elements apart, the whole piece would become weaker than they are together. It’s also a tongue-in-cheek argument about the polarity between handwork that has a functional role in the world, and the handwork that is found in museums and doesn’t have the same intended purpose, as far as utility. (Even though I feel that art is absolutely necessary.) There’s this polarity that keeps these craft worlds and art worlds separated, and inside my world that never has been an issue at all.

LT: You always felt that way? You started out primarily doing blacksmithing, in a functional sense.

They were two parallel paths. As a teenager, I wanted to be able to make a living doing what I enjoy. The practical side of making useful objects that people needed was one part of it. But at the same time, I was making public art projects and working with several galleries in Santa Fe, Megan Hills Gallery, Okun, and LewAllen, and little by little, they began to provide enough support that it was half and half. I was able to have one foot in the world of providing useful objects—which included contemporary architectural work, furniture, lighting fixtures, but I had started out making farm tools and restoring objects for local museums: the history museum had Spanish Colonial iron that I would replicate parts for so that they could put the pieces on exhibit, and the Palace of the Governors had many printing presses I worked on restoring. I try to convey as much as I can in the current work that none of it would be what it is today were it not for these influences early on. I don’t create any kind of hierarchy about those processes or what provided livelihood at any given moment.

Clayton Porter: What is it like to have older pieces around? You have a lot of pieces on your property now, but I imagine a lot of these pieces are going to go somewhere.

Some of the works are part of series. I keep exploring new possibilities as new material becomes available, scaling them up or tweaking them in different ways. Everywhere I look is a loose end. Having older work visible in the studio lets me know that at any point I can pick up that thread and move it in directions that, five, ten, fifteen years ago, weren’t possible because I was thinking differently. There’s all this potential tied up. And I like looking at it. I’ve been going through all my old sketchbooks, and when I made the originals, I felt a responsibility to the students, apprentices, and interns who had come to work with me, to teach them basics, so I probably stayed with the functional work longer than I might have otherwise. I’ve begun questioning that now, at sixty years old, saying, “Okay, you’ve got how many years of endurance to do work that is physically demanding, how do I want to utilize that time? I feel totally exhilarated by the possibilities at the factory, and being given this opportunity. I feel like I’ve barely utilized it. Even though there’s a lot of work to see, what I wake up with every morning is something that doesn’t exist yet.

The investment in materials, the investment in my own work, that’s all that has ever played out in a positive way. If I put money in the bank, it just disappears. When the MacArthur Fellowship came through, within a month I was already at the factory. I worked there for five years in a row, just anted it all up. I knew that I could always fall back on the hammer in my hand, and that would create the conditions whereby, if the next day there was nothing left in the pie, I could still make something to survive.

CP: Can you tell us about these photographs?

This, for me, is an origin story recording the moment of iron’s birth in ingot form. For the last ten years I’ve been photographing the ends of these thirty- and forty-thousand-pound ingots. The ingots are the raw material that the factory uses to forge all kinds of industrial products. By photographing the end of it, I see all the impurities that create these wild colors. Different chemical elements—silica, manganese, aluminum, dirt, grease—all kinds of materials rise up out of the molten pool of iron and settle in this lake that shrinks away and shows the grain that develops inside. All this lineation has a grain as unique as the human fingerprint or a piece of wood. A lot of steel looks like a homogenous product that you’d never guess had that kind of individuality. The ingot is about six feet in diameter, so I wanted to represent it as big as it could be so you could feel, going into it, that you’re not sure if it’s a photograph of something microscopic or a satellite view of earth from space.

I have access to materials that are among the strongest, most durable, most rust-resistant materials in the world, and it’s really a phenomenal playground of possibilities. I try to manipulate and exploit something that’s inherent in its grain structure that allows a viewer to experience it as if you’re looking at it through a microscope. It pulls to the surface something that you wouldn’t be able to see otherwise.

LT: There’s a sort of “primary-ness” here in New Mexico that I’m drawn to, and I feel that in your work. Do you feel the work takes on different guises in different locations? Is it received differently?

I would say that the work, out of context, is received differently. These works are about the geology, about the lateritic soil that we find in a lot of places in the West. If somebody’s not living in an erosive landscape, I don’t know if they would naturally gravitate toward a rusty piece of metal. The fact that these sculptures are made from a very high-carbon steel means that the velvety surface that you see on it—that is a rainwater-induced rust—it will always be like that; it’s not like corten that will eventually rust away in the rust belt of the Mid-West, or other places with a salty environment. That won’t happen to these pieces. For me, they have a geologic kinship with desert varnish, this darkened, rain- and mineral-induced striation. This sculpture is being shipped to London, so we’ll see what happens. Does it respond favorably in those weather conditions? Is it responded to favorably by people who will encounter that work in a public space? It’s hard to say. Does Georgia O’Keeffe’s work, out of context, play the same role? Some of her work does; but some of it, you really need the landscape to posit it in its full, fleshed-out experience. You could think of many different artists who are working here, and some of the work feels of this place, even Bruce Nauman’s video Setting a Good Corner [2000]—or, certainly the work that Susan Rothenberg has painted here, you feel the place.

LT: What’s next, with your work moving in these new directions?

Many artists experience a moment in their careers where they can see a path towards success, where the work is responded to really well. Maybe there’s a gallerist who really likes the direction you’re going in, and you have a choice about sticking with that or moving on. Whenever I feel that acceptance, man, I turn 180 degrees and try to figure out another path, even though you’d have to see all of my work at once to know that. People are familiar with some of my works now, but when they were first shown, the pieces were a dramatic departure from what everyone had expected. The desire is always to say, “This is only the beginning. How can I push it further?”