Take a tour of the printing press where each issue of The Magazine comes to life!

I know we make it look super slick and easy: content + design = printed mag in your hands. However, the printing process in itself requires many moving parts, people, and processes that bring each issue into physical reality. While it takes weeks and months to plan each issue, create our written content, secure imagery, and layout each article, the printing process compacts an enormous project into two days.

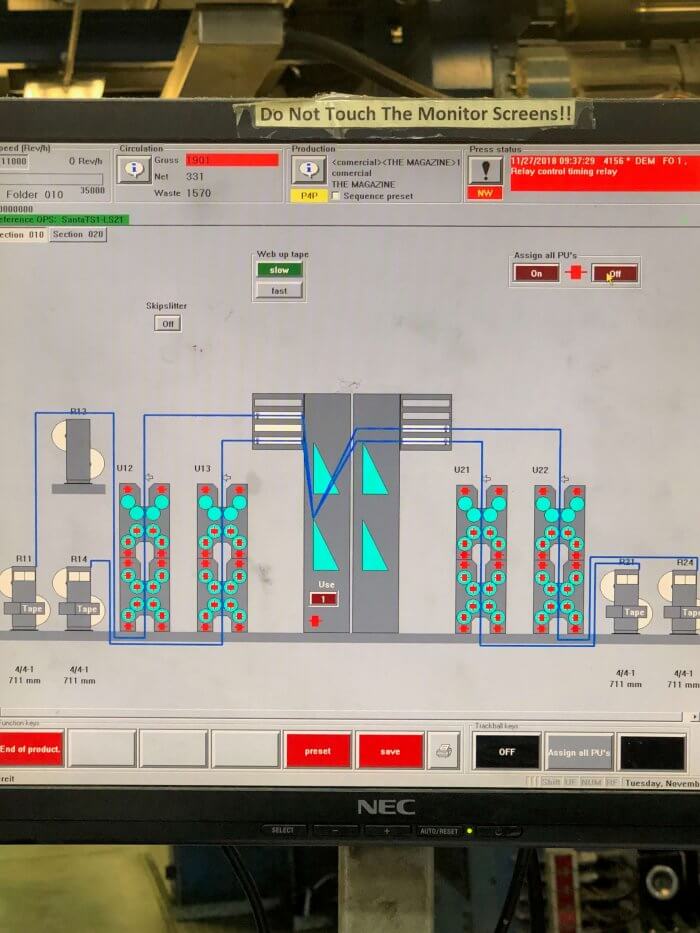

One of the coolest parts of the production process (for me) is the press check at the Santa Fe New Mexican (The Magazine’s printer for the last 10+ years). Every issue, I go down to take a look at the first copies coming off the press to make sure everything looks just right.

Starting with our digital files, the prepress specialists create color-separated plates (in cyan, magenta, yellow, and black) for each folio. These plates are made into cylinders for the web press, in which a continuous roll of paper passes over each cylindrical plate. While the web press is running, there are upwards of eight people working the press, continuously checking the for correct color, ink saturation, and registration. The folios are then folded, cut, stapled, trimmed, stacked, and bound. When the whole operation is fully staffed, there can be up to sixty people on the floor, divided up between each part of the operation. It’s a physically involved yet refined kind of work that requires extensive knowledge of the machines and an eye for the ink. It takes three full years to learn all aspects of the process through the New Mexican’s apprenticeship program.

After everything is close to the desired look, we take a close look at each page and make a few more subtle corrections for color and ink saturation. Once everything is finalized, they continue with our print run (11,000-14,000 issues depending on the month), and we get to work on distribution!